Opinions on Accelerating the Development of Energy Conservation and Environmental Protection Industry

2019-03-12

A few days ago, the Ministry of Industry and Information Technology and the General Administration of Quality Supervision, Inspection and Quarantine jointly issued the ''Notice on Organizing and Implementing the Motor Energy Efficiency Improvement Plan (2013-2015) ''(Ministry of Industry and Information Technology Lianjie (2013) No. 226), which plans to take 3 years to organize And mobilize the power of the entire system, through policy guidance, standard constraints, supervision and inspection and other means, as well as market-oriented operating mechanisms, from the field of motor production, application and recycling and remanufacturing, we will comprehensively improve motor energy efficiency and promote the transformation and upgrading of the motor industry. The reporter interviewed the relevant person in charge of the Ministry of Industry and Information Technology.

Q: Please briefly introduce the background of the organization and implementation of the motor energy efficiency improvement plan.

Answer: The 18th National Congress of the Communist Party of China clearly proposed to vigorously promote the construction of ecological civilization, requiring that the construction of ecological civilization be placed in a prominent position, integrated into all aspects and the entire process of economic construction, political construction, cultural construction, and social construction, and strive to promote energy production and utilization. revolution. Industry is the most important industry that consumes energy, resources, and produces environmental pollution. Energy consumption accounts for more than 70% of the country's total energy consumption. The main pollutants chemical oxygen demand (COD) and sulfur dioxide emissions account for about 40% and 85% of the country respectively. about. On the one hand, the sustainable development, transformation and upgrading of the industry itself requires us to vigorously promote energy and resource conservation. On the other hand, industry also undertakes the important task of providing energy-saving and emission-reduction equipment and products for the whole society. Implementing the spirit of the 18th National Congress of the Communist Party of China requires us to pay close attention to industrial energy conservation and consumption reduction, promote energy conservation in production processes and manufacturing processes in key industries and key areas, and at the same time pay more attention to the energy conservation of a wide range of end-use energy equipment, in order to promote energy production and Contribute to the revolution in utilization methods and the construction of a resource-saving and environment-friendly society.

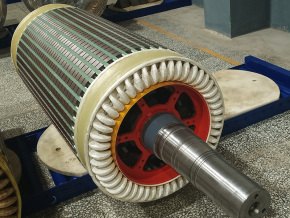

The motor is a driving device that drives various equipment such as fans, pumps, compressors, machine tools, and transmission belts. It is widely used in industry, agriculture, transportation, municipal and other industries and fields. It is the largest power consumption terminal equipment. In 2011, the number of motors in my country was about 1.7 billion kilowatts, and the total power consumption was about 3 trillion kilowatt-hours. Motor power consumption accounted for 64% of the total power consumption of the whole society and 75% of industrial power consumption. At the same time, the average efficiency of my country's motors is 3-5 percentage points lower than that of foreign countries, and the operating efficiency of motor systems (motors and drag equipment) is 10-20 percentage points lower than that of foreign countries. It is estimated that every one percentage point increase in motor energy efficiency can save more than 26 billion kilowatt-hours of electricity every year; if the efficiency of the motor system is increased by 5-8 percentage points, the annual electricity saving is equivalent to the power generation of 2-3 Three Gorges power stations. Such a huge power consumption and power-saving potential must be the focus of our industrial energy conservation, and it also requires us to make up our minds and work hard to study and organize implementation.

In addition, improving motor energy efficiency involves all aspects, that is, including motor production and use, but also with the motor production enterprises supporting the upstream materials, equipment, downstream fans, pumps, compressors and other enterprises and waste motor recycling and remanufacturing areas. To this end, on the one hand, we must integrate existing policies, accelerate the formation of a complete policy system covering the entire industrial chain of motor production, supporting, use, recycling and efficient remanufacturing, and make full use of incentive and restraint mechanisms to promote the transformation and upgrading of the motor industry. On the other hand, we hope to explore market-oriented models and methods to promote the improvement of motor energy efficiency by integrating resources and building platforms, so that motor manufacturers, supporting companies, user companies, energy-saving service companies, financial institutions, and efficient remanufacturing companies. All aspects have benefits, and the market mechanism has been fully utilized. Through the efforts of the above two aspects, we will build a new industrial energy-saving model that combines policy guidance, standard constraints and market-oriented operations. As an attempt to transform government functions and adapt to the government's macro management requirements under the new situation, it also lays the foundation for the subsequent implementation of special actions to improve the energy efficiency of industrial energy products such as internal combustion engines and industrial boilers.

Q: In the current economic downturn environment, what are the benefits of the implementation of motor energy efficiency improvement for enterprises? What is the contribution to promoting economic growth and industrial restructuring?

Answer: On the surface, the implementation of the motor energy efficiency improvement plan requires enterprises to purchase a large number of high-efficiency motors to replace the low-efficiency motors in use. Under the current economic downturn and the pressure of enterprise production and operation, it seems inappropriate for enterprises to invest in energy-saving transformation of motor systems. In fact, on the contrary, through a series of policy measures to comprehensively improve the energy efficiency of motors, it will not only bring tangible economic benefits to enterprises, stimulate the market demand for efficient motors, and promote the optimization of the motor industry structure, but also guide and stimulate society. Funds are invested in the field of energy conservation and environmental protection, which plays a positive role in expanding domestic demand.

From the perspective of motor production, on the one hand, in 2012, China promulgated and implemented the national mandatory standard of "energy efficiency limits and energy efficiency grades for small and medium-sized three-phase asynchronous motors" (GB18613-2012). compared with this standard, 90% of low-voltage three-phase asynchronous motor manufacturers in China are facing the problem of transformation and upgrading, that is, the energy efficiency of motor products is improved by at least one grade (energy efficiency is improved by more than 3%), which is the national mandatory standard, there is no room for bargaining. On the other hand, since 2010, the state has implemented a financial subsidy policy for high-efficiency motors for energy-saving products benefiting the people, and has given subsidies to production enterprises included in the national high-efficiency motor promotion catalogue, and the amount and scope of subsidies have been continuously expanded. The financial subsidy has been increased from 15-60 yuan to 31-100 yuan. This year, the downstream supporting products of motors such as fans, clear water centrifugal pumps, and air compressors have been included in the scope of subsidies. The implementation of the country's constraints and incentive policies will accelerate the optimization and adjustment of the motor industry structure.

From the perspective of motor users, on the one hand, we will strengthen the special supervision of the use of high energy consumption and backward motors by key users in accordance with relevant laws and regulations, and guide enterprises to accelerate the energy-saving transformation of motor systems. On the other hand, we will integrate professional energy-saving service companies, financial institutions, third-party energy-saving certification institutions and other resources to promote the energy-saving transformation mode of contract energy management for users' motor systems. Users only need to provide low-efficiency motor elimination and motor system energy-saving transformation requirements, without spending a penny, can be completed by the energy-saving service company energy-saving diagnosis, scheme design and system transformation tasks, users can completely "sit back and enjoy the benefits", and the follow-up can also share the real power-saving benefits. In this way, a large number of energy-saving transformation of motor systems will stimulate the demand market for high-efficiency motors, drive the production of more high-efficiency motor products in the field of motor production, and will also stimulate investment in financial and other social institutions, which will play a positive role in expanding domestic demand.

Q: Please introduce the general idea and goal of improving motor energy efficiency

Answer: The general idea of improving motor energy efficiency is: guided by the scientific development concept, in accordance with the requirements of the "Twelfth Five-Year Plan" for industrial energy conservation, with the goal of improving motor energy efficiency, focusing on key links such as motor production, use, recycling and remanufacturing, Accelerate the elimination of inefficient motors, vigorously develop and promote high-efficiency motor products, and expand the market share of high-efficiency motors; accelerate the implementation of energy-saving transformation of motor systems, establish and improve the waste motor recycling mechanism, promote efficient remanufacturing of motors; strengthen policy support and guidance, improve testing methods, strengthen standards and constraints, strict market access, strengthen supervision and management, and gradually establish an implementation mechanism that combines incentives and constraints, comprehensively improve the energy efficiency of motors, and promote the motor industry Transformation and upgrading to promote the smooth completion of the "Twelfth Five-Year" energy conservation and emission reduction targets.

The motor energy efficiency improvement plan proposes that by 2015, motor products will be upgraded, and 50% of low-voltage three-phase cage asynchronous motor products and 40% of high-voltage motor products will meet the energy efficiency standards for high-efficiency motors. A total of 0.17 billion kilowatts of high-efficiency motors will be promoted, 0.16 billion kilowatts of low-efficiency motors will be eliminated, 0.1 billion kilowatts of energy-saving technological transformation of motor systems will be implemented, and 20 million kilowatts of high-efficiency remanufacturing of motors will be eliminated. It is estimated that 80 billion kilowatt-hours of electricity will be saved in 2015, equivalent to 26 million tons of standard coal and 68 million tons of carbon dioxide emission reduction.

In addition, we hope to achieve four goals:

(I) motor industry to achieve transformation and upgrading. Through the implementation of mandatory motor energy efficiency standards in the supply link, motor manufacturers are encouraged to independently develop a batch of high-efficiency motor products, guide the adjustment of the industry structure, eliminate a batch, integrate a batch, and reorganize a batch to optimize the organizational structure of motor manufacturers.

(II) cultivate a number of contract energy management companies. Cultivate a group of contract energy management companies with strong technical capabilities, high service quality, and strong resource integration capabilities, and explore an operation model that is more in line with market needs.

(III) establish an energy-saving mechanism for market-oriented investment operations. Explore a market-oriented energy-saving model with the direction of government guidance, the implementation of business entities, and the participation of social institutions. This is our very important goal.

(IV) explore the long-term mechanism of industrial energy conservation. Coordinate relevant government departments, mobilize the strength of the whole system, jointly organize and implement, establish linkage between the upper and lower levels, coordinate with each other, and promote a long-term mechanism for energy conservation in key industrial areas and key products.

Q: What specific measures will be taken to promote the implementation of such a large system project as the improvement of motor energy efficiency?

Answer: There are two key links in the improvement of motor energy efficiency, one is the motor manufacturer, and the other is the motor user enterprise.

For motor manufacturers, we will work with the General Administration of Quality Supervision, Inspection and Quarantine to organize a special inspection of the implementation of national mandatory energy efficiency standards by motor manufacturers, that is, before the end of this year, the company will pass self-inspection and rectification, and the motor products produced must meet the national motor. Minimum energy efficiency standard requirements. If the expiration is still not up to the standard, it will be closed or punished in accordance with relevant laws and regulations, which is clearly stipulated in the Energy Saving Law. At the same time, we should inform the relevant departments of the list of enterprises and product models that do not meet the standards for public exposure. Banks do not give loans and users are not allowed to purchase. If in this process, the motor production enterprises to transform, we support, need to reorganize, we encourage. This work is a hard measure and a hard task to control the production of inefficient motors by production enterprises from the source. At the same time, we will also make full use of energy-saving products Huimin project efficient motor promotion and other series of financial subsidies to guide the upgrading of motor product structure.

For motor user enterprises, the focus is to promote the elimination of inefficient motors and energy-saving transformation of motor systems. We will organize key electric industrial enterprises to conduct self-examination with reference to the Catalogue of Elimination of High Energy Consumption and Backward Electromechanical Equipment (Products) and the Roadmap for Elimination of Low-efficiency Motors in Use. We will encourage enterprises to combine the elimination of low-efficiency motors with the energy-saving transformation of motor systems, and to promote the promotion of high-efficiency motors, the elimination of low-efficiency motors, and the matching transformation between motors and driving equipment. We require key power consumption enterprises with annual power consumption of more than 10 million kilowatt hours to formulate a three-year (2013-2015) motor system transformation plan on the basis of self-examination, and list the transformation schedule, path and mode. We will integrate market resources such as energy-saving service companies, energy-saving certification agencies, and financial institutions, and vigorously promote the energy management contract model for energy-saving transformation of motor systems. We do not require enterprises to complete all the transformation within one year, but it should be basically realized within three years. At the same time, we will organize supervision forces to carry out special supervision against the enterprise transformation plan, and give support to those with remarkable results and demonstration effect; for enterprises with inactive attitude, elimination and lagging progress of energy-saving transformation, we will take necessary measures and make public exposure.

In addition, there are two key tasks, one is to promote the efficient remanufacturing of waste motors. Including the establishment of a standardized recycling system for waste motors, the promotion of high-efficiency motor remanufacturing technology, and the formation of high-efficiency motor remanufacturing standards. The second is to speed up the research and application of high-efficiency motor technology. Including the selection of a number of high-efficiency motor design, control, matching and key materials and equipment and other fields of advanced technology, the release of advanced applicable technology catalog. For advanced technologies, good power-saving effects, and suitable for large-scale transformation, pilot demonstration projects will be carried out, and special promotion plans will be formulated.

Q: we are concerned about the motor energy efficiency improvement plan proposed to focus on the key power industry enterprises, this is how to consider?

A: according to statistics, there are more than 30000 key power consumption industrial enterprises with an annual power consumption of more than 10 million kilowatt hours, accounting for about 80% of the total industrial power consumption. Key power consumption enterprises are essential to achieve the objectives and tasks of the motor energy efficiency improvement plan. Highlight the improvement of motor energy efficiency in key power-consuming enterprises, based on three considerations:

First, the Energy Conservation Law has clear requirements for key energy-using enterprises. Articles 54, 16, and 17 of the Energy Conservation Law have clear provisions on energy-saving measures, energy utilization efficiency, and mechanisms and systems for eliminating outdated energy-using equipment for key power consumption enterprises. This is the legal responsibility of key energy-using enterprises. Second, the state has clear requirements for key energy-using enterprises. The "Notice of the State Council on Printing and Distributing the Comprehensive Work Plan for Energy Conservation and Emission Reduction during the" Twelfth Five-Year Plan "and the" Notice on Printing and Distributing the Implementation Plan for Energy Conservation and Low-Carbon Action of Ten Thousand Enterprises "by 12 ministries and commissions also require 10,000 enterprises to follow laws and regulations, industrial policies and The government planning requires that backward production capacity be eliminated on schedule, and energy-using equipment and production processes that are explicitly eliminated by the state must not be used. It is necessary to speed up the renovation of old motors and actively use the high-efficiency and energy-saving motors that are the focus of the state. Third, key electricity companies should assume more social responsibilities. Key power consumption industrial enterprises have large energy consumption, large emissions, and relatively large energy-saving potential, which is the focus of energy conservation and emission reduction. At the same time, the key power industry enterprises have standardized management, strong technical support and resource integration capabilities, and the pressure of tightening resource and environmental constraints requires key enterprises to assume more social responsibilities. We hope that key power consumption industrial enterprises will take energy conservation and emission reduction as the height of sustainable development of enterprises, enhance core competitiveness and establish a good image of enterprises, implement the national policy of improving motor energy efficiency, make achievements and set an example, and form a demonstration and guiding role from point to area. To this end, we propose to combine the improvement of motor energy efficiency with the assessment of energy saving and emission reduction targets of key enterprises, and do a good job in improving the energy efficiency of motors in key power consumption enterprises.

Q: Why is it proposed to vigorously promote the contract energy management model for energy-saving transformation of motor systems?

Answer: Contract energy management is a new type of market-oriented energy-saving incentive mechanism. Energy-saving service companies operating based on this mechanism, through signing contracts with energy-using units, provide energy-saving diagnosis, scheme design, financing, transformation and other one-stop services for energy-using units, and recover investment and obtain reasonable profits in various ways such as energy-saving benefit sharing. The energy-saving transformation of the motor system refers to the overall consideration of the motor and the driving equipment as a system, I .e. enterprises are encouraged to replace the inefficient motor with the efficient motor first when formulating the motor energy efficiency improvement transformation plan, and then carry out the matching transformation between the motor and the driving equipment, so as to realize the coordinated promotion of the objectives and tasks such as the promotion of the efficient motor, the elimination of the inefficient motor, and the matching transformation of the motor and the driving equipment.

Contract energy management mode to promote the motor system energy-saving transformation has so several benefits. One is economic benefit. According to estimates, if only low-efficiency motors are replaced with high-efficiency motors, the power saving rate is only about 3%. Compared with the cost of one-time bulk purchase of high-efficiency motors, the investment payback period is longer, generally more than 8 years, and the enthusiasm of enterprises is not high. If the appropriate technology is used to replace the inefficient motor with the efficient motor, and then the matching transformation between systems is carried out. In many fields, the power saving rate can reach more than 15% (in some fields, it can reach more than 50%). In this way, the payback period of investment is generally about 2 years (some less than 1 year), and both enterprises and energy-saving service companies are more active. Second, users can achieve zero input. Energy-saving service companies can choose different modes such as energy-saving benefit sharing type (energy-saving quantity guarantee type, energy-saving benefit sharing type, equipment rental type) to carry out energy-saving transformation of motor system according to the requirements of enterprises. Without investing a penny in advance, the energy-saving service company can carry out energy-saving transformation of the motor system through financing or other channels, which greatly improves the feasibility of the promotion plan. Third, the power saving effect is better. The energy-saving transformation of the motor system involves the integration of electrical balance testing, scheme design, system optimization and other technologies, with strong professionalism and high technical content. Professional energy-saving service companies have more advantages than key users, and the power-saving effect of the motor system will be better.

In the contract energy management mode to promote the motor system energy-saving transformation, we have dozens of mature technologies and typical application cases, the effect is very good. In the next step, we will select and release a group of contract energy management companies that master core technologies, high service quality, and strong resource integration capabilities, and recommend them to key power companies. And establish a docking and cooperation platform between contract energy management companies, key users, third-party energy-saving certification institutions, and financial institutions. Through a market-oriented model of mutual recognition and mutual restraint, the confidence of enterprises in energy-saving transformation of motor systems is further improved and risks are reduced.

A few days ago, the Ministry of Industry and Information Technology and the General Administration of Quality Supervision, Inspection and Quarantine jointly issued the ''Notice on Organizing and Implementing the Motor Energy Efficiency Improvement Plan (2013-2015) ''(Ministry of Industry and Information Technology Lianjie (2013) No. 226), which plans to take 3 years to organize And mobilize the power of the entire system, through policy guidance, standard constraints, supervision and inspection and other means, as well as market-oriented operating mechanisms, from the field of motor production, application and recycling and remanufacturing, we will comprehensively improve motor energy efficiency and promote the transformation and upgrading of the motor industry. The reporter interviewed the relevant person in charge of the Ministry of Industry and Information Technology.

Q: Please briefly introduce the background of the organization and implementation of the motor energy efficiency improvement plan.

Answer: The 18th National Congress of the Communist Party of China clearly proposed to vigorously promote the construction of ecological civilization, requiring that the construction of ecological civilization be placed in a prominent position, integrated into all aspects and the entire process of economic construction, political construction, cultural construction, and social construction, and strive to promote energy production and utilization. revolution. Industry is the most important industry that consumes energy, resources, and produces environmental pollution. Energy consumption accounts for more than 70% of the country's total energy consumption. The main pollutants chemical oxygen demand (COD) and sulfur dioxide emissions account for about 40% and 85% of the country respectively. about. On the one hand, the sustainable development, transformation and upgrading of the industry itself requires us to vigorously promote energy and resource conservation. On the other hand, industry also undertakes the important task of providing energy-saving and emission-reduction equipment and products for the whole society. Implementing the spirit of the 18th National Congress of the Communist Party of China requires us to pay close attention to industrial energy conservation and consumption reduction, promote energy conservation in production processes and manufacturing processes in key industries and key areas, and at the same time pay more attention to the energy conservation of a wide range of end-use energy equipment, in order to promote energy production and Contribute to the revolution in utilization methods and the construction of a resource-saving and environment-friendly society.

The motor is a driving device that drives various equipment such as fans, pumps, compressors, machine tools, and transmission belts. It is widely used in industry, agriculture, transportation, municipal and other industries and fields. It is the largest power consumption terminal equipment. In 2011, the number of motors in my country was about 1.7 billion kilowatts, and the total power consumption was about 3 trillion kilowatt-hours. Motor power consumption accounted for 64% of the total power consumption of the whole society and 75% of industrial power consumption. At the same time, the average efficiency of my country's motors is 3-5 percentage points lower than that of foreign countries, and the operating efficiency of motor systems (motors and drag equipment) is 10-20 percentage points lower than that of foreign countries. It is estimated that every one percentage point increase in motor energy efficiency can save more than 26 billion kilowatt-hours of electricity every year; if the efficiency of the motor system is increased by 5-8 percentage points, the annual electricity saving is equivalent to the power generation of 2-3 Three Gorges power stations. Such a huge power consumption and power-saving potential must be the focus of our industrial energy conservation, and it also requires us to make up our minds and work hard to study and organize implementation.

In addition, improving motor energy efficiency involves all aspects, that is, including motor production and use, but also with the motor production enterprises supporting the upstream materials, equipment, downstream fans, pumps, compressors and other enterprises and waste motor recycling and remanufacturing areas. To this end, on the one hand, we must integrate existing policies, accelerate the formation of a complete policy system covering the entire industrial chain of motor production, supporting, use, recycling and efficient remanufacturing, and make full use of incentive and restraint mechanisms to promote the transformation and upgrading of the motor industry. On the other hand, we hope to explore market-oriented models and methods to promote the improvement of motor energy efficiency by integrating resources and building platforms, so that motor manufacturers, supporting companies, user companies, energy-saving service companies, financial institutions, and efficient remanufacturing companies. All aspects have benefits, and the market mechanism has been fully utilized. Through the efforts of the above two aspects, we will build a new industrial energy-saving model that combines policy guidance, standard constraints and market-oriented operations. As an attempt to transform government functions and adapt to the government's macro management requirements under the new situation, it also lays the foundation for the subsequent implementation of special actions to improve the energy efficiency of industrial energy products such as internal combustion engines and industrial boilers.

Q: In the current economic downturn environment, what are the benefits of the implementation of motor energy efficiency improvement for enterprises? What is the contribution to promoting economic growth and industrial restructuring?

Answer: On the surface, the implementation of the motor energy efficiency improvement plan requires enterprises to purchase a large number of high-efficiency motors to replace the low-efficiency motors in use. Under the current economic downturn and the pressure of enterprise production and operation, it seems inappropriate for enterprises to invest in energy-saving transformation of motor systems. In fact, on the contrary, through a series of policy measures to comprehensively improve the energy efficiency of motors, it will not only bring tangible economic benefits to enterprises, stimulate the market demand for efficient motors, and promote the optimization of the motor industry structure, but also guide and stimulate society. Funds are invested in the field of energy conservation and environmental protection, which plays a positive role in expanding domestic demand.

From the perspective of motor production, on the one hand, in 2012, China promulgated and implemented the national mandatory standard of "energy efficiency limits and energy efficiency grades for small and medium-sized three-phase asynchronous motors" (GB18613-2012). compared with this standard, 90% of low-voltage three-phase asynchronous motor manufacturers in China are facing the problem of transformation and upgrading, that is, the energy efficiency of motor products is improved by at least one grade (energy efficiency is improved by more than 3%), which is the national mandatory standard, there is no room for bargaining. On the other hand, since 2010, the state has implemented a financial subsidy policy for high-efficiency motors for energy-saving products benefiting the people, and has given subsidies to production enterprises included in the national high-efficiency motor promotion catalogue, and the amount and scope of subsidies have been continuously expanded. The financial subsidy has been increased from 15-60 yuan to 31-100 yuan. This year, the downstream supporting products of motors such as fans, clear water centrifugal pumps, and air compressors have been included in the scope of subsidies. The implementation of the country's constraints and incentive policies will accelerate the optimization and adjustment of the motor industry structure.

From the perspective of motor users, on the one hand, we will strengthen the special supervision of the use of high energy consumption and backward motors by key users in accordance with relevant laws and regulations, and guide enterprises to accelerate the energy-saving transformation of motor systems. On the other hand, we will integrate professional energy-saving service companies, financial institutions, third-party energy-saving certification institutions and other resources to promote the energy-saving transformation mode of contract energy management for users' motor systems. Users only need to provide low-efficiency motor elimination and motor system energy-saving transformation requirements, without spending a penny, can be completed by the energy-saving service company energy-saving diagnosis, scheme design and system transformation tasks, users can completely "sit back and enjoy the benefits", and the follow-up can also share the real power-saving benefits. In this way, a large number of energy-saving transformation of motor systems will stimulate the demand market for high-efficiency motors, drive the production of more high-efficiency motor products in the field of motor production, and will also stimulate investment in financial and other social institutions, which will play a positive role in expanding domestic demand.

Q: Please introduce the general idea and goal of improving motor energy efficiency

Answer: The general idea of improving motor energy efficiency is: guided by the scientific development concept, in accordance with the requirements of the "Twelfth Five-Year Plan" for industrial energy conservation, with the goal of improving motor energy efficiency, focusing on key links such as motor production, use, recycling and remanufacturing, Accelerate the elimination of inefficient motors, vigorously develop and promote high-efficiency motor products, and expand the market share of high-efficiency motors; accelerate the implementation of energy-saving transformation of motor systems, establish and improve the waste motor recycling mechanism, promote efficient remanufacturing of motors; strengthen policy support and guidance, improve testing methods, strengthen standards and constraints, strict market access, strengthen supervision and management, and gradually establish an implementation mechanism that combines incentives and constraints, comprehensively improve the energy efficiency of motors, and promote the motor industry Transformation and upgrading to promote the smooth completion of the "Twelfth Five-Year" energy conservation and emission reduction targets.

The motor energy efficiency improvement plan proposes that by 2015, motor products will be upgraded, and 50% of low-voltage three-phase cage asynchronous motor products and 40% of high-voltage motor products will meet the energy efficiency standards for high-efficiency motors. A total of 0.17 billion kilowatts of high-efficiency motors will be promoted, 0.16 billion kilowatts of low-efficiency motors will be eliminated, 0.1 billion kilowatts of energy-saving technological transformation of motor systems will be implemented, and 20 million kilowatts of high-efficiency remanufacturing of motors will be eliminated. It is estimated that 80 billion kilowatt-hours of electricity will be saved in 2015, equivalent to 26 million tons of standard coal and 68 million tons of carbon dioxide emission reduction.

In addition, we hope to achieve four goals:

(I) motor industry to achieve transformation and upgrading. Through the implementation of mandatory motor energy efficiency standards in the supply link, motor manufacturers are encouraged to independently develop a batch of high-efficiency motor products, guide the adjustment of the industry structure, eliminate a batch, integrate a batch, and reorganize a batch to optimize the organizational structure of motor manufacturers.

(II) cultivate a number of contract energy management companies. Cultivate a group of contract energy management companies with strong technical capabilities, high service quality, and strong resource integration capabilities, and explore an operation model that is more in line with market needs.

(III) establish an energy-saving mechanism for market-oriented investment operations. Explore a market-oriented energy-saving model with the direction of government guidance, the implementation of business entities, and the participation of social institutions. This is our very important goal.

(IV) explore the long-term mechanism of industrial energy conservation. Coordinate relevant government departments, mobilize the strength of the whole system, jointly organize and implement, establish linkage between the upper and lower levels, coordinate with each other, and promote a long-term mechanism for energy conservation in key industrial areas and key products.

Q: What specific measures will be taken to promote the implementation of such a large system project as the improvement of motor energy efficiency?

Answer: There are two key links in the improvement of motor energy efficiency, one is the motor manufacturer, and the other is the motor user enterprise.

For motor manufacturers, we will work with the General Administration of Quality Supervision, Inspection and Quarantine to organize a special inspection of the implementation of national mandatory energy efficiency standards by motor manufacturers, that is, before the end of this year, the company will pass self-inspection and rectification, and the motor products produced must meet the national motor. Minimum energy efficiency standard requirements. If the expiration is still not up to the standard, it will be closed or punished in accordance with relevant laws and regulations, which is clearly stipulated in the Energy Saving Law. At the same time, we should inform the relevant departments of the list of enterprises and product models that do not meet the standards for public exposure. Banks do not give loans and users are not allowed to purchase. If in this process, the motor production enterprises to transform, we support, need to reorganize, we encourage. This work is a hard measure and a hard task to control the production of inefficient motors by production enterprises from the source. At the same time, we will also make full use of energy-saving products Huimin project efficient motor promotion and other series of financial subsidies to guide the upgrading of motor product structure.

For motor user enterprises, the focus is to promote the elimination of inefficient motors and energy-saving transformation of motor systems. We will organize key electric industrial enterprises to conduct self-examination with reference to the Catalogue of Elimination of High Energy Consumption and Backward Electromechanical Equipment (Products) and the Roadmap for Elimination of Low-efficiency Motors in Use. We will encourage enterprises to combine the elimination of low-efficiency motors with the energy-saving transformation of motor systems, and to promote the promotion of high-efficiency motors, the elimination of low-efficiency motors, and the matching transformation between motors and driving equipment. We require key power consumption enterprises with annual power consumption of more than 10 million kilowatt hours to formulate a three-year (2013-2015) motor system transformation plan on the basis of self-examination, and list the transformation schedule, path and mode. We will integrate market resources such as energy-saving service companies, energy-saving certification agencies, and financial institutions, and vigorously promote the energy management contract model for energy-saving transformation of motor systems. We do not require enterprises to complete all the transformation within one year, but it should be basically realized within three years. At the same time, we will organize supervision forces to carry out special supervision against the enterprise transformation plan, and give support to those with remarkable results and demonstration effect; for enterprises with inactive attitude, elimination and lagging progress of energy-saving transformation, we will take necessary measures and make public exposure.

In addition, there are two key tasks, one is to promote the efficient remanufacturing of waste motors. Including the establishment of a standardized recycling system for waste motors, the promotion of high-efficiency motor remanufacturing technology, and the formation of high-efficiency motor remanufacturing standards. The second is to speed up the research and application of high-efficiency motor technology. Including the selection of a number of high-efficiency motor design, control, matching and key materials and equipment and other fields of advanced technology, the release of advanced applicable technology catalog. For advanced technologies, good power-saving effects, and suitable for large-scale transformation, pilot demonstration projects will be carried out, and special promotion plans will be formulated.

Q: we are concerned about the motor energy efficiency improvement plan proposed to focus on the key power industry enterprises, this is how to consider?

A: according to statistics, there are more than 30000 key power consumption industrial enterprises with an annual power consumption of more than 10 million kilowatt hours, accounting for about 80% of the total industrial power consumption. Key power consumption enterprises are essential to achieve the objectives and tasks of the motor energy efficiency improvement plan. Highlight the improvement of motor energy efficiency in key power-consuming enterprises, based on three considerations:

First, the Energy Conservation Law has clear requirements for key energy-using enterprises. Articles 54, 16, and 17 of the Energy Conservation Law have clear provisions on energy-saving measures, energy utilization efficiency, and mechanisms and systems for eliminating outdated energy-using equipment for key power consumption enterprises. This is the legal responsibility of key energy-using enterprises. Second, the state has clear requirements for key energy-using enterprises. The "Notice of the State Council on Printing and Distributing the Comprehensive Work Plan for Energy Conservation and Emission Reduction during the" Twelfth Five-Year Plan "and the" Notice on Printing and Distributing the Implementation Plan for Energy Conservation and Low-Carbon Action of Ten Thousand Enterprises "by 12 ministries and commissions also require 10,000 enterprises to follow laws and regulations, industrial policies and The government planning requires that backward production capacity be eliminated on schedule, and energy-using equipment and production processes that are explicitly eliminated by the state must not be used. It is necessary to speed up the renovation of old motors and actively use the high-efficiency and energy-saving motors that are the focus of the state. Third, key electricity companies should assume more social responsibilities. Key power consumption industrial enterprises have large energy consumption, large emissions, and relatively large energy-saving potential, which is the focus of energy conservation and emission reduction. At the same time, the key power industry enterprises have standardized management, strong technical support and resource integration capabilities, and the pressure of tightening resource and environmental constraints requires key enterprises to assume more social responsibilities. We hope that key power consumption industrial enterprises will take energy conservation and emission reduction as the height of sustainable development of enterprises, enhance core competitiveness and establish a good image of enterprises, implement the national policy of improving motor energy efficiency, make achievements and set an example, and form a demonstration and guiding role from point to area. To this end, we propose to combine the improvement of motor energy efficiency with the assessment of energy saving and emission reduction targets of key enterprises, and do a good job in improving the energy efficiency of motors in key power consumption enterprises.

Q: Why is it proposed to vigorously promote the contract energy management model for energy-saving transformation of motor systems?

Answer: Contract energy management is a new type of market-oriented energy-saving incentive mechanism. Energy-saving service companies operating based on this mechanism, through signing contracts with energy-using units, provide energy-saving diagnosis, scheme design, financing, transformation and other one-stop services for energy-using units, and recover investment and obtain reasonable profits in various ways such as energy-saving benefit sharing. The energy-saving transformation of the motor system refers to the overall consideration of the motor and the driving equipment as a system, I .e. enterprises are encouraged to replace the inefficient motor with the efficient motor first when formulating the motor energy efficiency improvement transformation plan, and then carry out the matching transformation between the motor and the driving equipment, so as to realize the coordinated promotion of the objectives and tasks such as the promotion of the efficient motor, the elimination of the inefficient motor, and the matching transformation of the motor and the driving equipment.

Contract energy management mode to promote the motor system energy-saving transformation has so several benefits. One is economic benefit. According to estimates, if only low-efficiency motors are replaced with high-efficiency motors, the power saving rate is only about 3%. Compared with the cost of one-time bulk purchase of high-efficiency motors, the investment payback period is longer, generally more than 8 years, and the enthusiasm of enterprises is not high. If the appropriate technology is used to replace the inefficient motor with the efficient motor, and then the matching transformation between systems is carried out. In many fields, the power saving rate can reach more than 15% (in some fields, it can reach more than 50%). In this way, the payback period of investment is generally about 2 years (some less than 1 year), and both enterprises and energy-saving service companies are more active. Second, users can achieve zero input. Energy-saving service companies can choose different modes such as energy-saving benefit sharing type (energy-saving quantity guarantee type, energy-saving benefit sharing type, equipment rental type) to carry out energy-saving transformation of motor system according to the requirements of enterprises. Without investing a penny in advance, the energy-saving service company can carry out energy-saving transformation of the motor system through financing or other channels, which greatly improves the feasibility of the promotion plan. Third, the power saving effect is better. The energy-saving transformation of the motor system involves the integration of electrical balance testing, scheme design, system optimization and other technologies, with strong professionalism and high technical content. Professional energy-saving service companies have more advantages than key users, and the power-saving effect of the motor system will be better.

In the contract energy management mode to promote the motor system energy-saving transformation, we have dozens of mature technologies and typical application cases, the effect is very good. In the next step, we will select and release a group of contract energy management companies that master core technologies, high service quality, and strong resource integration capabilities, and recommend them to key power companies. And establish a docking and cooperation platform between contract energy management companies, key users, third-party energy-saving certification institutions, and financial institutions. Through a market-oriented model of mutual recognition and mutual restraint, the confidence of enterprises in energy-saving transformation of motor systems is further improved and risks are reduced.

Previous Page: