Motor Efficiency in Ground Source Heat Pump System

Release time:

2024-07-28

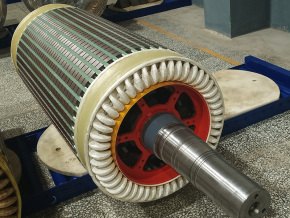

High efficiency motor asked

All kinds of motors used in the ground source heat pump system can be divided into two categories according to the working efficiency of the motor: standard efficiency motor and high efficiency motor. Compared with the standard efficiency motor, the high efficiency motor can be 2 to 10 percentage points higher according to the power. The high efficiency motor is realized through better design and the use of special materials that can reduce the loss, but the price is about 10% to 30% of the standard efficiency motor. Therefore, only 1/5 of the motors sold in the world are high efficiency motors. Motor efficiency is the ratio of mechanical power output to power input, usually expressed as a percentage, and Figure 1 shows the difference between a standard motor and a high-efficiency motor, which is produced by improved design materials and technology to produce more work per unit of power consumption.

In general, high-efficiency motors usually have a high load factor, better insulation and withstand voltage, and low heat generation and less vibration, thereby increasing reliability. High efficiency motors must be equal to or exceed the full load efficiency of ordinary motors specified by the International Electrical Manufacturers Association (NEMA). In other words, a motor efficiency must equal or exceed the NEMA high-efficiency motor full-load engineering efficiency value to be called a high-efficiency motor. The cost of a high-efficiency motor depends on: motor price, efficiency, use time, installation and maintenance costs, and labor costs. The additional acquisition costs of high-efficiency motors can be quickly recovered by saving operating costs, and usually the additional costs of high-efficiency motors can be offset by the energy savings of two years of operation. For example, assuming that a 50hp, 75% load factor motor runs more than 4000h per year and the electricity bill is $0.04/kWh, one improvement point can save 4079kwh or $163 per year. Therefore, a high-efficiency motor, through a 4% efficiency improvement, can save $1304 in two years compared with a standard motor, which basically meets the two-year return standard.

The relationship between motor speed and load

Centrifugal pumps and fan loads are extremely sensitive to speed changes, and a mere 5r/min increase in speed can lead to a significant increase in flow rate and energy consumption and a decrease in efficiency. Therefore, when replacing a pump or fan, the full load speed must be selected to be equal to or lower than the speed of the motor to be replaced. The power on the centrifugal motor driving the fan is proportional to the cube of the speed. For example, if the motor speed is increased from 1740r/min to 1760r/min, although only 20r/min is increased, the power consumption will be increased by 3.5, and the air volume or water volume will also change with the square of the speed. Slip and speed depend on the load, which makes it possible for different motors to drive the same load. For example, when a 100hp motor outputs 25% rated power, it can be replaced by a 50hp or lower horsepower motor, except that the power at this time is 50% of 50hp, or 62.5 of 40hp, 83% of 30hp, and 25hp full load output. When the motor load gradually increases, the rotation speed will decrease, and the rotation speed at full load is the full load rotation speed. Therefore, Anhui Electric Motor suggests that only the motor with lower speed or larger load can operate at a speed close to the synchronous rotation speed, and the full load and high efficiency motor with smaller power can operate at a speed close to the synchronous rotation speed, replacing the original motor with larger power but low speed, which can obviously save the operation cost.

recommend News

The difference between DC motor and AC motor

2024-07-29

Share