Permanent Magnet Motors: Driving the Future of Energy-Efficient Industrial and Transportation Solutions

2026-01-09

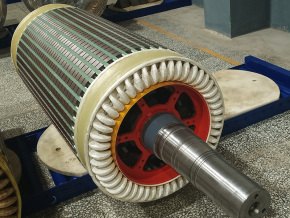

Permanent magnet motors (PMMs) are rapidly becoming a cornerstone of modern industrial and transportation systems due to their superior efficiency, compact design, and precise performance capabilities. Unlike traditional electric motors that require external excitation to generate a magnetic field, PMMs utilize high-performance permanent magnets to produce a stable magnetic field, resulting in higher efficiency, reduced energy losses, and smaller motor size. These characteristics make permanent magnet motors ideal for applications where space, energy consumption, and reliability are critical factors.

In the automotive sector, permanent magnet motors are driving the shift toward electric mobility. Electric vehicles (EVs), hybrid electric vehicles (HEVs), and plug-in hybrid electric vehicles (PHEVs) increasingly rely on PMMs for traction due to their high power density, precise torque control, and energy-saving capabilities. By using PMMs, EV manufacturers can reduce the size and weight of motor systems while maintaining optimal performance, extending vehicle range, and improving overall energy efficiency. Moreover, these motors contribute to quieter operation and lower maintenance costs compared to conventional induction motors, which further enhances the appeal of PMMs in automotive applications.

Industrial automation is another field experiencing significant growth in the adoption of permanent magnet motors. Manufacturing processes, robotics, conveyor systems, and precision machinery benefit from the compact footprint and precise speed and torque control that PMMs provide. By integrating PMMs into industrial systems, companies can improve production efficiency, reduce energy consumption, and ensure consistent operation even under variable load conditions. Additionally, the reduced heat generation and maintenance requirements of permanent magnet motors extend the service life of critical equipment, lowering operational costs and supporting sustainable manufacturing practices.

The renewable energy sector also leverages permanent magnet motors, particularly in wind turbines and solar tracking systems. PMMs are highly efficient at converting electrical energy into mechanical energy and vice versa, which makes them well-suited for variable-speed wind turbines and other renewable energy applications. Their precise control capabilities allow for optimized energy capture, ensuring maximum efficiency even under fluctuating environmental conditions. By deploying permanent magnet motors, renewable energy operators can increase system reliability, reduce downtime, and improve overall energy yield.

Market trends indicate a strong growth trajectory for permanent magnet motors. According to industry reports, the demand for energy-efficient and compact motor solutions is expected to rise significantly in the next decade, driven by the global push for sustainability, carbon emission reduction, and energy cost savings. Technological advancements in magnet materials, motor design, and manufacturing processes further enhance the performance and affordability of PMMs, making them increasingly accessible across a wide range of applications.

Furthermore, PMMs are playing a critical role in rail transit and urban transportation systems. High-efficiency traction motors for subways, light rail, and high-speed trains are increasingly based on permanent magnet technology, offering reduced energy consumption, smoother operation, and lower maintenance compared to traditional motors. These benefits not only enhance passenger comfort and operational reliability but also contribute to greener urban transportation networks by lowering the overall environmental footprint.

The versatility of permanent magnet motors extends to specialized applications as well. Stone-processing machinery, low-noise fan systems, auxiliary motors for locomotives, and servo-driven equipment all benefit from the precise control, energy efficiency, and long service life of PMMs. Industries requiring high reliability and durability increasingly prefer permanent magnet motors over conventional solutions, further solidifying their position as a key technology in modern industrial and transportation infrastructure.

In conclusion, permanent magnet motors represent a transformative technology in the drive toward energy efficiency, sustainability, and high-performance solutions across multiple industries. From electric vehicles to industrial automation, renewable energy, and rail transit, PMMs are redefining the capabilities of electric motor systems. With ongoing advancements in materials, design, and manufacturing, the future of permanent magnet motors looks promising, supporting global efforts to reduce energy consumption, lower emissions, and enable more reliable and efficient mechanical and electrical systems.

Previous Page:

Next page: